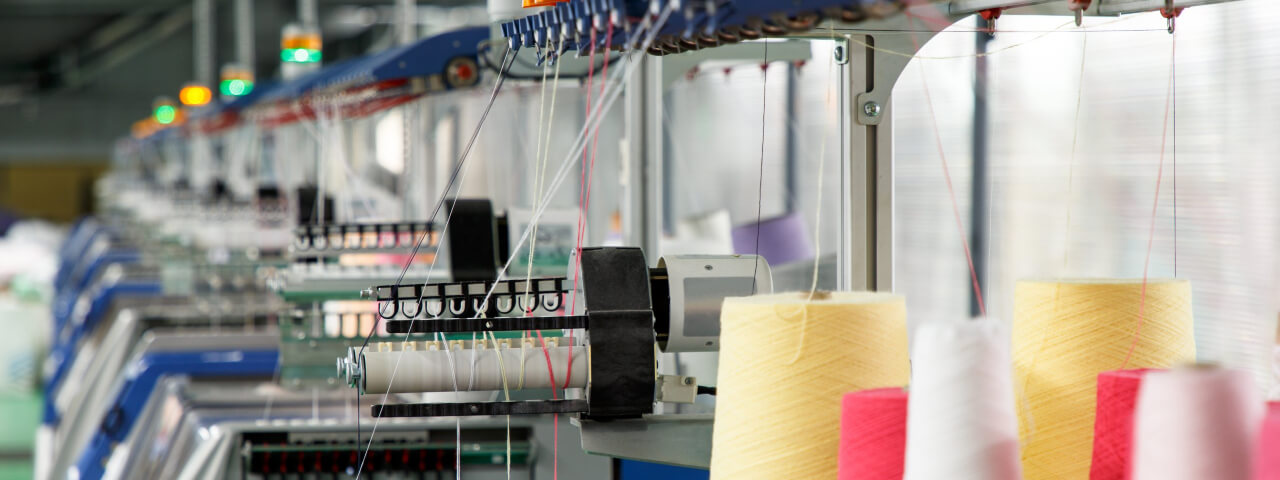

Stainless pipes and profiles have a critical role in the textile industry to increase the efficiency and lifetime of production machines. It provides continuous and uninterrupted production by ensuring the durability of machines used especially in processes such as fabric dyeing, yarn production and weaving. The corrosion resistance of stainless steel contributes to the long life of these machines in environments exposed to humid and chemical substances.

In textile production, materials that are not subject to abrasion and deformation under the influence of temperature and chemicals are of great importance. Stainless steel tubes and profiles can work without changing shape even at high temperatures. Thanks to these properties, textile machines operate with high performance and less maintenance, which reduces production costs.

In addition, with its structure that minimizes environmental impacts, stainless steel contributes to sustainable production targets in the textile industry. It has become a material preferred by textile companies by offering environmentally friendly solutions with both the energy efficiency it provides in production processes and its recyclable structure.